907

Color: Green

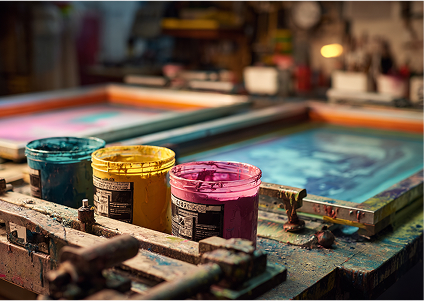

Plastisol Inks | All-Pro™ 900 Series

All-Pro™ 900 Series Plastisol Ink is a fast flashing, 2 part ink, specifically formulated for printing on normally hard to print Nylon.

All-Pro™ 900 Series Plastisol Ink is a fast flashing, 2 part ink, specifically formulated for printing on normally hard to print Nylon.

Being the industry standard for over 15 years, the ink’s harder finish resists scratching, scuffing and peeling for an extremely durable image.

It can also be used without catalyst on nonwoven polyporpylene bags (NPB) by adding up to 6% 3804 Low Cure Additive, which reduces cure temperatures down to 250°F (135ºC).

The All-Pro™ 900 Series Ink must be mixed with the All-Pro™ 900 Catalyst before printing on Nylon. Catalyst is available in 2 ounce, 8 ounce, and 1 gallon containers. The catalyst should be thoroughly mixed in to the ink to the following proportions:

By volume = 16 parts ink to 1 part catalyst

By weight = 20 parts ink to 1 part catalyst

Ink may be used immediately after mixing. Do not mix more ink than is needed for a job. Do not under-catalyze the ink. Pot life of mixed ink is 4 to 8 hours. Over-catalyzation will shorten the pot life.

If printing on cotton, it is not necessary to catalyze the ink. Print it as you would a normal direct print plastisol ink.

For standard colors, recommended screen mesh is 125-230 t/in (49-90 t/cm). For metallic colors, recommended screen mesh is 86-110 t/in (34-43 t/cm). For process colors,recommended screen mesh is 200-305 t/in (79-120 t/cm).

Adding too much reducer or other additives to the 900 Series inks may cause curing/fusing or increased dye migration problems. Test dryer temperatures and wash test printed product before and during a production run

Recommendations and statements made are based on International Coatings’ research and experience. Since International Coatings does not have any control over the conditions of use or storage of the product sold, International Coatings cannot guarantee the results obtained through use of its products. All products are sold and samples given without any representation of warranty, expressed or implied, of fitness for any particular purpose or otherwise, and upon condition that the buyer shall determine the suitability of the product for its own purpose. This applies also where rights of third parties are involved. It does not release the user from the obligation to test the suitability of the product for the intended purpose and application.

100% Cotton

Some Cotton/Polyester Blends

Nonwoven Polypropylene Bags (NPB)

Nylon

All-Pro™ 900 Series Ink must be mixed with the All-Pro™ 900 Catalyst before printing, for adhesion to Nylon substrates. For NPB, catalyst is not necessary.

If modification is necessary, use 1% to 5% by weight of 1110 Curable Reducer. For NPB, 3804 Low Cure Additive can be added up to 6% by weight to lower cure temperature.

110–305 t/in (43–120 t/cm) monofilament.

Any direct or indirect emulsion or capillary film in the 35 to 70 micron range

65–70 Durometer, sharp edge.

290°F (143°C) to 325ºF (163ºC) for one minute. Dependent on dryer speed and temperature settings.

Quart

1 Gallon

5 Gallon

30 Gallon

50 Gallon

65°F to 90°F (18°C to 32°C). Avoid storage in direct sunlight. Keep containers well sealed.

Any Eco-friendly plastisol screen wash

** Catalyst must be ordered separately.

+ Metallic colors require longer cure dwell times due to the reflective nature of the metallic flakes.

Explore our diverse range of products designed to meet your unique needs and applications.

Learn more