156

Color: Silver

Plastisol Inks | Metallic Shimmers

Metallic Shimmers are used to produce a bright, sparkled look when printed.

Metallic Shimmers are bleed resistant Shimmer Plastisols that are press ready.

Metallic Shimmers consist of a fine, shimmering glitter flakes in a low bleed, low fusion, easy to print base.

Metallic Shimmers are used to produce a bright, sparkled look when printed.

Metallic Shimmers are bleed resistant Shimmer Plastisols that are press ready.

Metallic Shimmers consist of a fine, shimmering glitter flakes in a low bleed, low fusion, easy to print base.

Metallic Shimmers can be printed onto a garment as is, or printed over other colors to highlight areas of a design. When printing multiple colors, Shimmers should be printed last. Shimmers should be printed without any modifications. If modification is necessary use the following reducer: 1099 Low Bleed Curable Reducer (Add 1% to 5% by weight).

Use International Coatings’ 7500 Series Fluorescents or Process Colors for tinting Shimmer to other shades. Do not mix Shimmers with opaque inks as they will block out or cover the Metallic Shimmers flake.

For better adhesion on some fabrics it may be necessary to add the 900 Catalyst for proper adhesion. The ratio of ink to catalyst is 16 parts ink to 1 part catalyst by volume and 20 to 1 by weight.

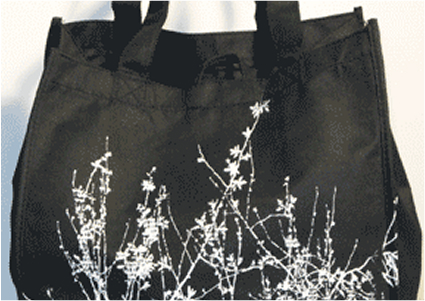

The Metallic Shimmers have good opacity on dark fabrics. However, in some instances, when printing through finer mesh counts, double hits with or without a flash may be needed. This is especially true when printing 157 or 158 Metallic Shimmers on dark fabrics.

Print Metallic Shimmers last in the design to avoid excessive pick-up of the shimmer flakes.

The time/temperature cycle is very important when printing through very open mesh screens. It may take the thicker ink film a little longer to reach the proper fusion temperature than a standard ink. Always test for proper fusing before and during a production run.

Recommendations and statements made are based on International Coatings’ research and experience. Since International Coatings does not have any control over the conditions of use or storage of the product sold, International Coatings cannot guarantee the results obtained through use of its products. All products are sold and samples given without any representation of warranty, expressed or implied, of fitness for any particular purpose or otherwise, and upon condition that the buyer shall determine the suitability of the product for its own purpose. This applies also where rights of third parties are involved. It does not release the user from the obligation to test the suitability of the product for the intended purpose and application.

100% Cotton

Cotton/Polyester Blends

100% Polyester

Metallic Shimmers should be used right from the container without any modifications

If modification is necessary, use 1% to 5% by weight of 1099 Low Bleed Curable Reducer

110–305 t/in (43–120 t/cm) monofilament.

Any direct or indirect emulsion or capillary film.

65–70 Durometer, sharp edge.

325°F (163°C) entire ink film.

Quart

1 Gallon

5 Gallon

30 Gallon

50 Gallon

65°F to 90°F (18°C to 32°C). Avoid storage in direct sunlight. Keep containers well sealed.

Any eco-friendly plastisol screen wash

Explore our diverse range of products designed to meet your unique needs and applications.

Learn more